DIY SCT410.3 2wd Conversion by Christian Hernandez

There is no doubt about it, the Tekno SCT410.3 is one of the best short course trucks in the industry with numerous wins at the national and international level. Team driver Christian Hernandez wanted to race his favorite four-wheel drive SC truck in the two-wheel drive class as well, not only has he managed to make that possible but also have great success with it! Read all details below:

"As many of you already know, the sct410.3 has been a dominant player in the short course world, and has been very successful. Over the past six months I have been extensively testing on carpet and dirt tracks. Due to the 2wd Sc class substantially growing I decided to convert my sct410.3 to a sct210”C”. The conversion process I will explain below is very user friendly and only requires the use of regular tools and a dremel!

The first modification you must make to the car is to remove the front drive shafts/CVAs and the front diff. This will allow you to reduce the overall chassis weight and reduce front weight bias, leave you with the spinning stub axles. No edremeling or permanent modification is needed at this step. The front gearbox is still being used, and I highly recommend leaving it there for sway bar purposes. This part of the car is still a very useful tuning aspect and there will be other ways to remove weight from the truck that I will discuss later.

Just remove the front driveshafts and differential, simple right?

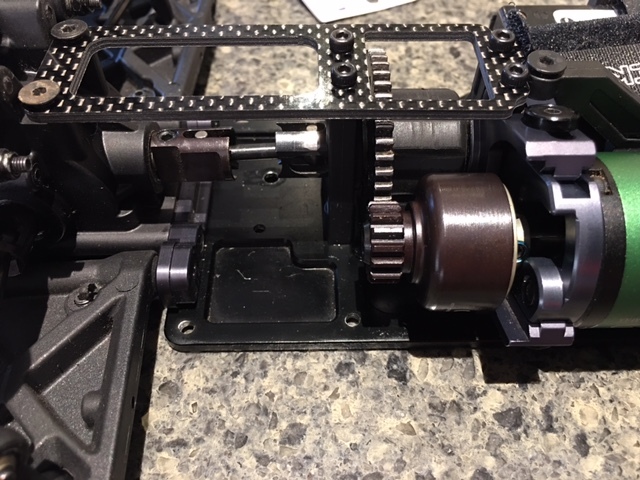

Moving to the central part of the chassis, the next step is removing the center front driveshaft being that is not used anymore. Going to the center differential, there are three ways to modify it 2wd friendly. The first option (which I use and HIGHLY RECOMMEND) is the simplest and easiest is filling the diff with 1 million diff fluid. This gives a feel similar to a slipper clutch and I personally have had the most success with this setup. When tuning the center differential, 200K for low traction and 500k-1million for medium-high traction are good options to have on differing surfaces and driving styles. With this setup, it is also recommend to use a shaft adapter (5mm-3.2mm) so you can run 2wd motors (540 style can).

1 million CST, yes that’s right!

Another option is running an electric clutch. I would only recommend this setup if you’re running a motor with a 5mm shaft. If you do run a clutch you must lock the diff with extra diff shims. By adding two diff shims to each side of the outdrives, the internal gears in the diff will start to mechanically bind, thus locking the diff. You can remove two spiders gears and one pin to reduce rotating mass here.

5mm motor shaft and electric clutch? Lock that diff!

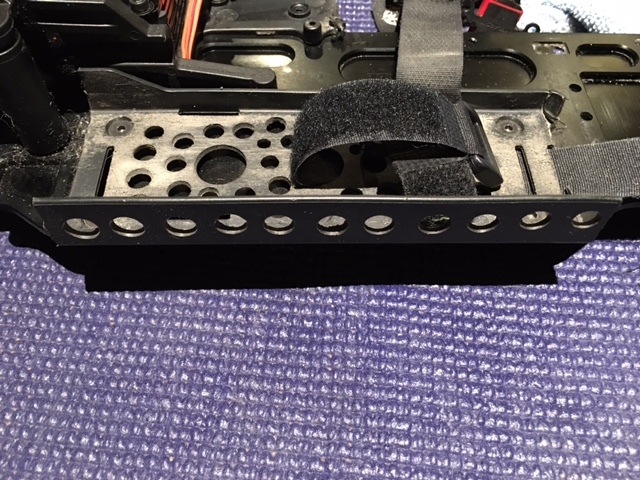

Another factor of the conversion (that is not essential but highly recommended) is reducing the weight by removing as much plastic material as possible. I first started off by removing the mechanical brake servo mount mount (behind the battery tray) and dremeling many holes into the battery tray itself (think Swiss cheese). On the opposite side of the chassis, I removed all plastic material behind the ESC tray and removed some plastic from the steering servo mount. These factors are all for weight reduction purposes and get the truck closer to the optimal weight. However, when doing these modifications I used all three chassis braces to make sure the chassis is not compromised for high traction surfaces like Astro and Carpet. However, when running on dirt I run a modified front chassis brace (Cut in half) which makes the chassis brace shorter and omit the other chassis braces. This allows the chassis to flex as much as possible to gain traction.

Moving our focus to the rear end of the car I did not cut, or do any modifications. However, I did venture out to other spring options. Stock rear Tekno springs can be used, but I found that using a front Tekno springs on the rear shocks proved to be way more consistent, have more corner speed, and be easier to drive, especially on carpet. Due to running on carpet, and limiting droop all around the shock is compressed a lot more and I felt that a more progressive spring such as a Tekno black front spring was perfect in this scenario. However, when running on dirt I felt running more droop and standard soft springs worked perfectly.

As I continued to test, electronics became an important factor. In my own testing, I found that a 540 two pole motor works best in this application and another area where you can reduce weight is by running a 1/10 motor and esc. As for servos, I would recommend still using the “standard servo” and unless you have a high quality “shorty servo” (MKS 575 SL or something similar). The sct210 conversion is still a heavy car so making sure your servos are over 175oz of torque is recommended. As for batteries I do recommend a shorty battery for weight purposes, and pushing it back as far as possible to add more rear weight bias.

Christian’s Tekno SCT210 conversion in all its glory!

Being that this platform is “shaft drive” and still excels as a 2wd is very surprising but I think you'll agree that it is very fun and easy to drive as it is very predictable and still holds to the Tekno standard. As always the car is very adaptable and still takes tuning changes well. I highly recommend trying this conversion if you have a sct410 platform!!!"

Please check a short video and Christian’s setups below: