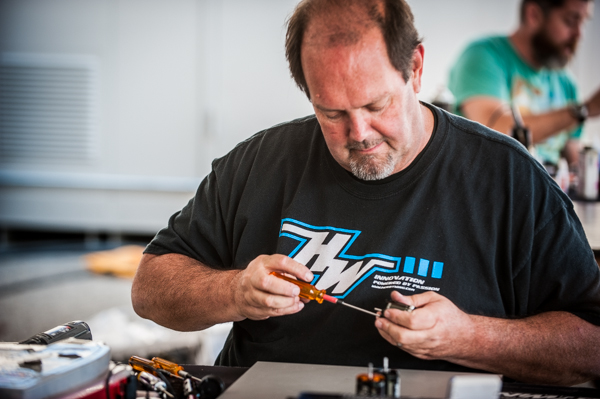

Most of us take for granted the ease and dependability of today’s brushless systems. They provide a level of technology that systems of years past can’t match. But, the components can be a mystery and the affects of changing or tuning them daunting. I sat down with HobbyWing and SchuurSpeed’s Ron Schuur to help explain rotors and the effects these little magnets have.

Ron Schuur is the Team Manager for HobbyWing and has his own line of Spec motors and accessories for his company SchuurSpeed.

RC Car Action: There’s a lot of talk among racers about rotors, but many people don’t know the differences. Can you help explain?

Ron Schuur: I get questions about them a lot. The important thing to know, is that the larger and more mass, the more torque you will have out of the motor. The smaller the mass, the more rpm you are going to get out of the motor. In the case of my SchuurSpeed motors, the standard rotor is 12.5mm diameter by 25mm long for a Spec motor. That’s legally the largest one you can run. We want to run with a lot of torque versus rpm in off-road, but touring car not as much, and 1/12-scale not at all. We offer varying sizes going down, with the next size being 12.5mm x 24, 12.3mm x 25, and as you go down you continue to pick up rpm in place of torque. The smallest one I have is a 12.1mm x 25. This works for guys who run cars like a Tamiya Mini who want crazy rpm, because they have fixed gears. 1/12-scale Spec racing, we run a lot of 12.3’s with varying length depending on who you are how you drive and in touring cars we run a 12.5mm x 24 or even a 12.3mm depending on the track and needed rpm.

When you run mod, that kind of flips the thinking?

Mod it changes. The Spec motor has a core rotor size of roughly 7.15mm, while the mod ones have typically 5mm, with some 6mm. That’s the key difference between mod and Spec. So if you run a 12.5mm x 25 mod rotor, there’s a ton more mass and more torque and that can make the motor very hard to control. So when I work with the off-road guys, they start to drop it in size. Some guys will use a 12.1mm rotor with 5mm core. The stock rotor in the mod motor is 12.5mm and it will have too much bottom end, too much rip. It’s common to fine-tune with different rotors.

The post Choose The Right Rotor For Your Ride appeared first on RC Car Action.